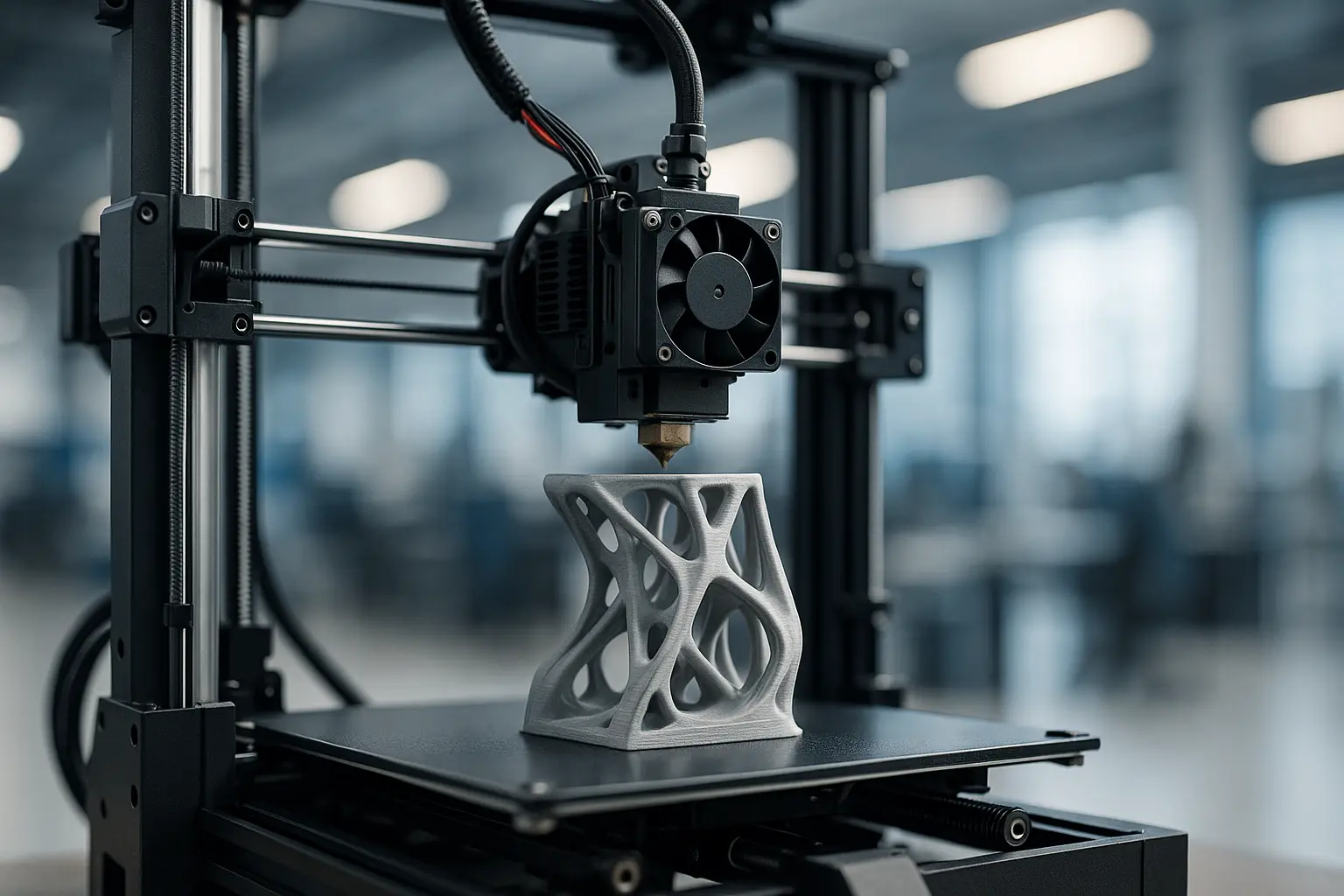

Imagine creating complex designs with ease, reducing production costs, and accelerating the prototyping process. Welcome to the world of additive manufacturing, a technology redefining how we approach design and production across various industries. As a collective society, we often find ourselves at the intersection of tradition and innovation. With 3D printing, we stand at a pivotal moment, embracing the potential to reshape our manufacturing landscape.

In this vibrant age of progress, additive manufacturing is not just a tool but a process that opens up a realm of possibilities. Whether you’re part of a development team tasked with crafting innovative products or a hobbyist exploring the art of creation, understanding additive manufacturing empowers us all to think beyond conventional boundaries.

Let’s embark on an exploration into the intricate yet fascinating world of 3D printing, where materials come to life, and production transforms into an art form.

Unveiling the Basics: Understanding Additive Manufacturing

When we talk about additive manufacturing, we refer to a revolutionary method of production that builds parts by adding material layer by layer. This starkly contrasts with traditional manufacturing techniques, which often require material removal to achieve desired shapes. Additive manufacturing offers the flexibility to create complex designs that would otherwise be impossible.

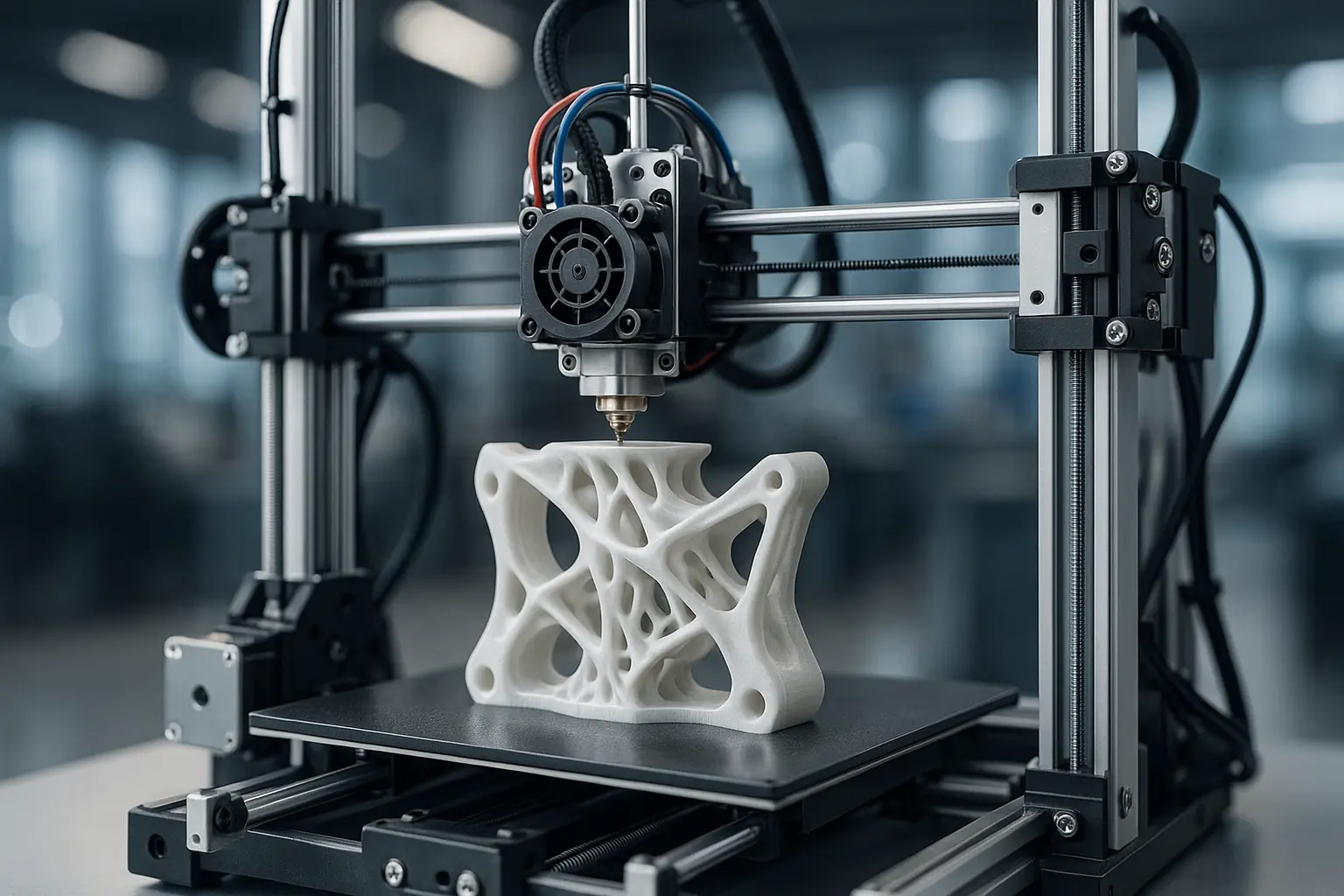

The beauty of this technology lies in its applications across a myriad of industries, from aerospace to healthcare. By utilizing 3D printing, manufacturers now have the ability to produce tailored components with precision, optimizing both time and resources. The method is particularly beneficial in rapid prototyping—allowing teams to iterate designs quickly without incurring excessive costs.

A key advantage of this process is its adaptability to different materials, including plastics, metals, and even ceramics. Such versatility allows industries to experiment and innovate with their product offerings. As manufacturers adopt 3D printing, they can bring products to market faster, responding to consumer demand with agility.

As we delve deeper into this technology, it’s clear that additive manufacturing doesn’t just complement traditional manufacturing—it challenges and enhances it, driving forward a new standard for production excellence.

Design and Development: The Heart of 3D Printing

In the realm of additive manufacturing, design is both king and queen. With the ability to fabricate complex geometries, 3D printing liberates the imagination, enabling creators to explore designs that were once confined to the realm of ideas. By leveraging additive technologies, designers are no longer bound by the constraints of traditional manufacturing methods.

In the development phase, additive manufacturing empowers teams to swiftly produce prototypes, facilitating an iterative approach. This capability is a game-changer, reducing lead times and allowing for greater creative freedom. As a result, the process of designing—be it for artistic endeavors or functional prototypes—becomes more dynamic and responsive.

Furthermore, additive manufacturing fosters collaboration in the design phase. Engineers, artists, and designers can work cohesively, utilizing technology to refine concepts and bring ideas to life. This synergy is crucial for developing products that are not only innovative but also highly functional.

By embracing this modern approach, designers and developers can harness the full potential of 3D printing, ensuring that products are not just manufactured but artfully crafted to meet an ever-evolving market.

Material Matters: Exploring the Versatility of Additive Manufacturing

In the world of additive manufacturing, the versatility of materials is a cornerstone of innovation. Unlike traditional manufacturing methods that often limit material choice, 3D printing opens the door to a vast array of materials, each offering unique properties and advantages.

From robust metals like titanium and steel to flexible polymers and ceramics, the array of materials available for additive manufacturing is expansive. This diversity allows industries to tailor their production strategies to specific needs, delivering products that are customized and high-performing.

The adaptability of 3D printing also extends to the creation of materials with enhanced properties. By manipulating the printing process, manufacturers can develop parts with increased strength, reduced weight, or improved thermal resistance. This has significant implications for sectors like aerospace and automotive, where material performance is paramount.

As we continue to explore the potential of additive manufacturing, it’s evident that the material landscape is as important as the technology itself. By investing in material research and development, we can ensure that 3D printing remains at the forefront of innovation, driving forward a new era of customized and efficient production.

As we stand on the brink of a new industrial revolution, additive manufacturing is poised to redefine manufacturing and design paradigms. The ability to create products with unparalleled efficiency, adaptability, and cost-effectiveness speaks volumes about the potential that 3D printing holds.

Looking towards the future, we can anticipate advancements in technology, further expansion of material capabilities, and increased integration into various industries. This synergy will not only enhance current processes but also pave the way for entirely new applications.

In embracing this modern approach, we all become architects of a new world—one where creativity meets precision, and complex ideas become tangible realities. As the journey continues, additive manufacturing will undoubtedly serve as a beacon of innovation, guiding us towards a future where the line between imagination and reality is beautifully blurred.

In this ever-evolving landscape, let’s remain curious, stay informed, and continue to explore the endless possibilities that additive manufacturing brings. Together, we can create a future where technology and creativity coexist, transforming the way we live, work, and create.

FAQ

What is additive manufacturing and how does it differ from traditional manufacturing?

Additive manufacturing, commonly known as 3D printing, is a process of creating objects by depositing material layer by layer, based on digital models. Unlike traditional manufacturing that often involves subtracting material through cutting or drilling, additive manufacturing builds objects from the ground up, reducing waste and allowing for greater design flexibility.

What materials can be used in additive manufacturing?

A wide range of materials can be utilized in additive manufacturing, including plastics, metals, ceramics, and even certain bio-materials. The choice of material largely depends on the intended application, desired properties, and the specific 3D printing technology employed.

How is additive manufacturing revolutionizing the prototyping process?

Additive manufacturing allows for rapid prototyping, enabling designers and engineers to quickly produce and test models. This accelerates the design process, allows for quicker iterations, and reduces the time and cost associated with developing new products. It also facilitates the creation of complex geometries that may be challenging or impossible to achieve with traditional methods.

What are the benefits of using 3D printing in production and manufacturing?

3D printing offers several advantages including reduced material waste, the ability to create complex and customized designs, shortened production lead times, and the potential for on-demand manufacturing. It also allows for localized production, reducing the need for large inventories and minimizing transportation requirements.

Are there any limitations or challenges associated with additive manufacturing?

Despite its many advantages, additive manufacturing faces challenges such as limited material selection compared to traditional methods, slower production speeds for large-scale items, and the need for post-processing steps to achieve certain finishes or properties. Additionally, the initial cost of 3D printing technology can be high, and there may be concerns related to intellectual property and quality control.